The rise of electric vehicles (EVs) has been a game-changer in the rapidly evolving automotive industry. As the world shifts towards greener and more sustainable modes of transportation, one of the critical components ensuring the efficiency, safety, and longevity of EVs is the battery thermal management system (BTMS). This system plays a pivotal role in maintaining the optimal temperature of the battery packs, thereby enhancing performance and extending battery life. Batteries, particularly lithium-ion ones, are sensitive to temperature fluctuations. Extreme temperatures can lead to reduced efficiency, shorter lifespan, and even hazardous situations like thermal runaway, which can cause fires or explosions. Hence, an effective BTMS is essential for maintaining optimal battery performance and safety. It regulates the temperature within the battery pack, ensuring it stays within a safe operating range.

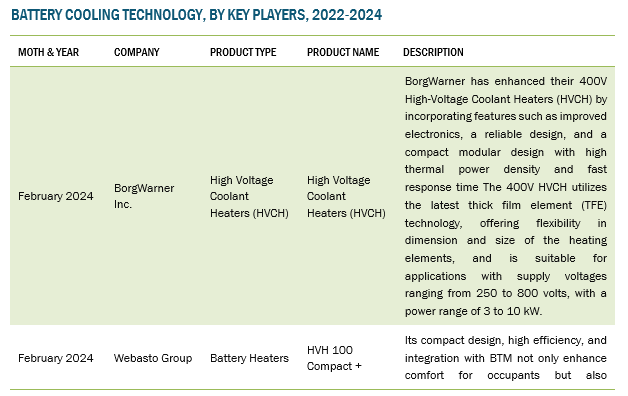

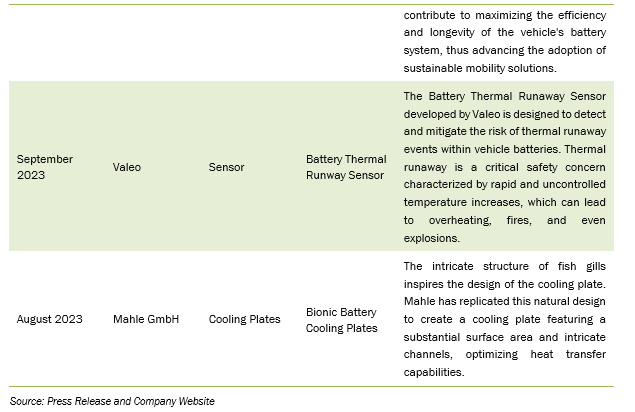

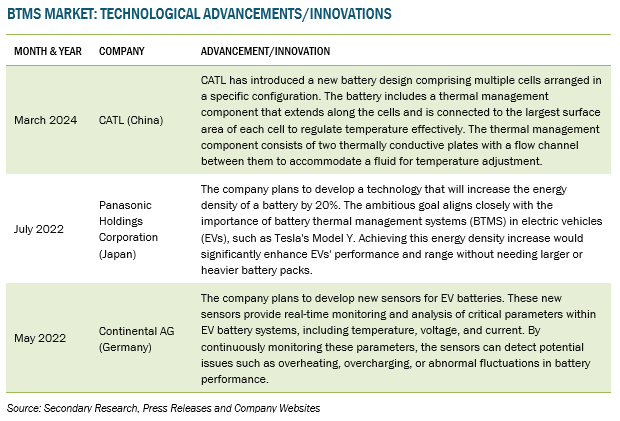

Market players like Robert Bosch GmbH, BorgWarner Inc., Continental AG, Webasto Group, Valeo, and others are investing heavily in BTMS technology to enhance its performance and lower their costs. This global shift towards sustainable transportation is driving the demand for electric vehicles. As this adoption grows, there is a parallel increase in the market for efficient battery thermal management systems for battery temperature, thus enhancing vehicle range and longevity. Governments worldwide are implementing stricter regulations to reduce emissions and improve energy efficiency. Compliance with these regulations necessitates using advanced BTMS to optimize battery performance and meet safety standards. Ongoing advancements in materials science, thermal engineering, and control systems present opportunities for innovation in BTMS technology. Solutions that offer higher efficiency, improved reliability, and enhanced safety features will find favor among manufacturers and end-users alike, driving market growth and competitiveness. The Chinese company XING Mobility, in January 2024, debuts its new BTMS technology Immersion Cooling Battery, which includes submerging battery cells in a thermally conductive dielectric fluid. The Tier 1 providers are launching new battery cooling technology as the demand for electric vehicles increases. The table below covers some of the latest technology launched by key players.

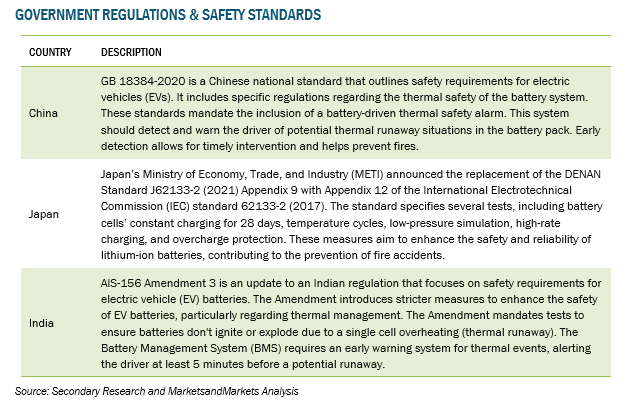

The BTMS Market is witnessing technological developments to meet OEMs demand and be future-ready. Electric vehicles have a lower operating cost than conventional vehicles. Increasing crude oil prices and the demand for eco-friendly mobility alternatives open opportunities for the BTMS market. The government in China introduced GB 18384-2020 standard that outlines safety requirements for electric vehicles (EVs). It includes specific regulations regarding the thermal safety of the battery system. These standards mandate the inclusion of a battery-driven thermal safety alarm. This system should detect and warn the driver of potential thermal runaway situations in the battery pack. Early detection allows for timely intervention and helps prevent fires. Similarly, the government’s introduction of safety norms in India, such as AIS-156 and AIS-038 (Rev 2) standards, following incidents like EV fires, has significantly impacted the BTMS market. By incorporating these safety measures, the government aims to mitigate safety risks associated with lithium-ion batteries, especially in regions with high ambient temperatures like tropical countries.

The BTMS Market is witnessing technological developments to meet OEMs demand and be future-ready. Electric vehicles have a lower operating cost than conventional vehicles. Increasing crude oil prices and the demand for eco-friendly mobility alternatives open opportunities for the BTMS market. The government in China introduced GB 18384-2020 standard that outlines safety requirements for electric vehicles (EVs). It includes specific regulations regarding the thermal safety of the battery system. These standards mandate the inclusion of a battery-driven thermal safety alarm. This system should detect and warn the driver of potential thermal runaway situations in the battery pack. Early detection allows for timely intervention and helps prevent fires. Similarly, the government’s introduction of safety norms in India, such as AIS-156 and AIS-038 (Rev 2) standards, following incidents like EV fires, has significantly impacted the BTMS market. By incorporating these safety measures, the government aims to mitigate safety risks associated with lithium-ion batteries, especially in regions with high ambient temperatures like tropical countries.

As per Amey Godbole, Associate Manager (Automotive and Transportation domain) at MarketsandMarkets Research, Major OEMs like Tesla and BYD integrate BTMS into the battery pack at their facilities, reflecting a trend where OEMs are more involved in the design and control of these systems with many other also practicing such methods. This trend will continue in the future, and there is a chance that these OEMs might include BTMS components such as cooling plates and thermal sensors while developing their battery pack”. Further, Jeet Shah, Senior Research Analyst (Automotive and Transportation domain) at MarketsandMarkets Research, “Favorable government regulatory policies and initiatives regarding battery safety coupled with growing awareness of emission-free vehicles will propel the market growth of BTMS in the near future.”

As per Amey Godbole, Associate Manager (Automotive and Transportation domain) at MarketsandMarkets Research, Major OEMs like Tesla and BYD integrate BTMS into the battery pack at their facilities, reflecting a trend where OEMs are more involved in the design and control of these systems with many other also practicing such methods. This trend will continue in the future, and there is a chance that these OEMs might include BTMS components such as cooling plates and thermal sensors while developing their battery pack”. Further, Jeet Shah, Senior Research Analyst (Automotive and Transportation domain) at MarketsandMarkets Research, “Favorable government regulatory policies and initiatives regarding battery safety coupled with growing awareness of emission-free vehicles will propel the market growth of BTMS in the near future.”

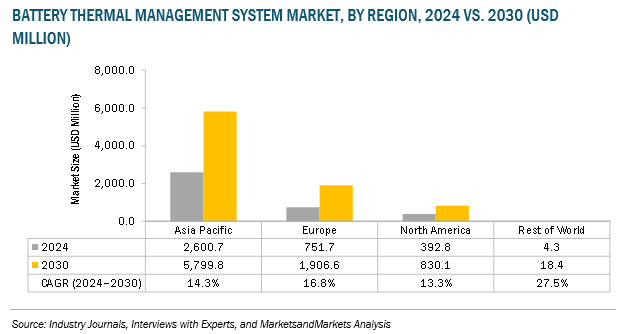

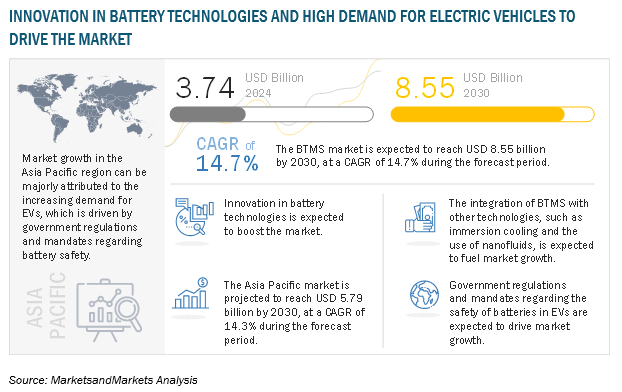

According to MarketsandMarkets, the global BTMS market is projected to reach USD 8.55 billion by 2030, from USD 3.74 billion in 2024 and growing at a CAGR of 14.7%. The market growth is governed by improvements in battery technology and supporting government policies and regulations for electric vehicles.

KEY DRIVING FACTOR FOR BTMS MARKET

Innovation in EV battery system

Innovations in cathode chemistry, such as lithium nickel manganese cobalt oxide (NMC), lithium nickel cobalt aluminum oxide (NCA), and lithium iron phosphate (LFP), have led to higher energy densities and improved range in EV batteries. However, these advancements also bring challenges in terms of thermal management. Higher energy densities can lead to increased heat generation during charging and discharging cycles, which, if not properly managed, can degrade battery performance and lifespan. For instance, the Tesla Model S uses LFP batteries. Tesla has developed a new battery design in which the cooling ribbons are now glued directly to the cooling ribbon, and the cooling ribbon spans a greater percentage of the cells’ height.

Stringent regulatory and safety standards

Stringent regulatory and safety standards

Government regulations impact various aspects such as battery safety norms, safety requirements for battery cells and management systems, design standards for battery packs, and measures to prevent thermal propagation and fires resulting from internal cell short circuits. The global push to reduce vehicle emissions and promote electric vehicles (EVs) has led to significant investments in BTMS, particularly in countries like Norway and Germany. For instance, in January 2024, the partnership between Bosch’s Rexroth (Germany) and Modine Manufacturing (US) emphasizes the development of customized thermal management solutions tailored to the specific requirements and operating conditions of off-highway applications.

The government’s introduction of safety norms in India, such as AIS-156 and AIS-038 (Rev 2) standards, following incidents like EV fires, has significantly impacted the BTMS market. These standards emphasize battery safety, electric vehicle safety, and additional safety requirements for battery cells and management systems. By incorporating these safety measures, the government aims to mitigate safety risks associated with lithium-ion batteries, especially in regions with high ambient temperatures like tropical countries.

KEY STRATEGIES BY MARKET PLAYERS

BlackRock and Temasek Lead USD 150 Million Investment in Thermal Battery Maker Antora Energy

BlackRock and Temasek, two leading global investment firms, have spearheaded a consortium to invest USD 150 million in Antora Energy, a company specializing in thermal battery technology. This significant funding round underscores the growing interest and confidence in innovative energy storage solutions. Antora Energy’s thermal batteries aim to provide sustainable and efficient energy storage by converting excess renewable energy into heat, which can be converted back to electricity when needed. This technology addresses a critical challenge in the renewable energy sector by ensuring a reliable energy supply even when renewable sources like solar and wind are not producing power. The investment from BlackRock and Temasek is expected to accelerate the development and deployment of Antora’s thermal battery systems, potentially transforming energy storage and contributing to global efforts to transition to cleaner energy sources.

BorgWarner and FinDreams Battery Forge International strategic partnership for LFP battery packs integrated with BTMS

BorgWarner, a prominent automotive supplier, has entered into an international strategic relationship agreement with FinDreams Battery, a subsidiary of BYD specializing in battery technology. This collaboration focuses on lithium iron phosphate (LFP) battery packs, which are integrated with battery cooling and are known for their safety, long cycle life, and cost-effectiveness. The agreement aims to leverage FinDreams Battery’s expertise in LFP technology and battery cooling products to enhance BorgWarner’s electric vehicle offerings. By incorporating these advanced battery packs, BorgWarner seeks to improve its electric propulsion systems’ performance, efficiency, and sustainability. This partnership is expected to drive innovation and accelerate the adoption of electric vehicles globally, aligning with the automotive industry’s shift towards greener technologies.

BY: MARKETSANDMARKETS